ARC150P Arc Spray System

Overview

A complete push arc spraying system combining our NEW ARC150P pistol and Model 500 Amp Energiser.

Our new ARC150P pistol includes many parts that are industrial 3D printed from a lightweight, carbon fibre reinforced plastic. This makes the pistol lightweight for the operator but incredibly strong and durable.

We have retained our proven Arc geometry but have created a pistol that is virtually maintenance free.

Our energiser and drive unit now feature robust, industrial connections as standard. Current adjustment is via a new, dustproof push button which also incorporates fault status feedback.

The drive unit has an additional top set of driven rollers for a robust wire feed. Our latest trolley is compact and designed to keep the supplies connections out of the spray area and free from dust.

All this combined with our high quality supplies packages and high performance rates makes our range of push systems the easiest to use on the market.

Features

- Profiled Drive Rollers

- Maintenance Free Gearbox

- Adjustable Wire Tension

- Compact Design

- Lighter Weight

- Quick release MIG carriers

- Supplies Package:

- Industrial Twist & Lock Connections

- Robust Manifold and Cover

- Lightweight Cooled Conductors

- Push Pistol:

- Light and Robust

- Industrial 3D Printed Parts

- Carbon Fiber Reinforced

- Ergonomic Design

- Energizer:

- Fan on Demand

- Push Button Current Control

- Sturdy Harting Connections

- Rear Handle

Documents

Applications

- Structural Steelwork

- Oil and Gas Platforms

- Pipes and Vessels

- Internal Vessels and Boilers

- Gates and Fences

- Architectural Fabrications

- Bridges

Accessories

Accessories can help the operator and increase productivity.

Arc Spray Process

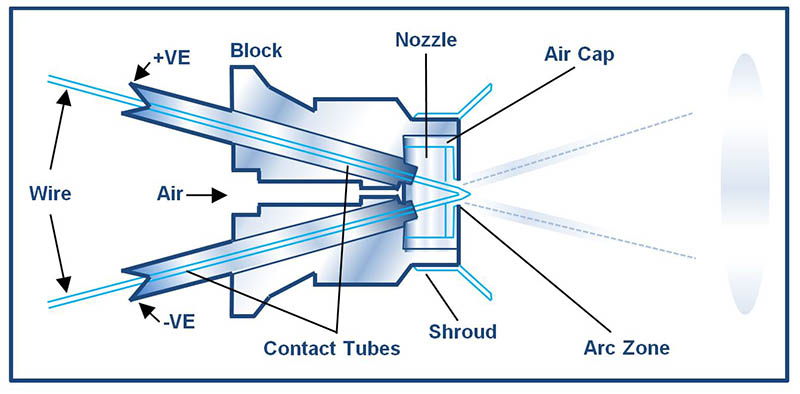

Arc spray (sometimes referred to as twin wire arc spray) is a process that uses an electric arc to melt wires.

The molten metal is then atomised with compressed air to create a spray stream that applies the coating onto the surface being sprayed.

Anti-corrosion or engineering coatings can be applied by arc spray and changing between the two is quite simple.

Arc spray systems are commonly considered to be easy to operate and also to automate.

Metallisation have a full range of arc spray systems for hand-held and fully automatic / robotic applications.