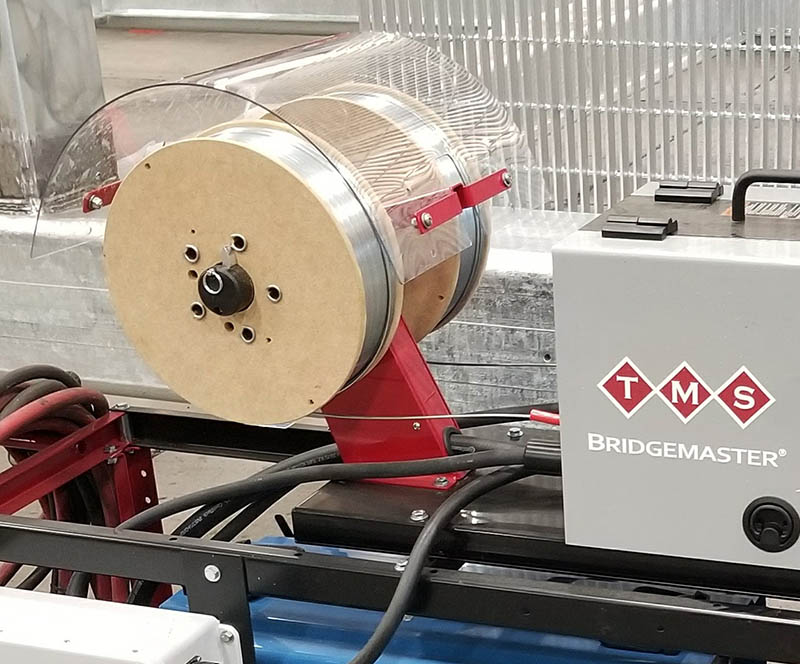

TMS Bridgemaster® Arc Spray System

Overview

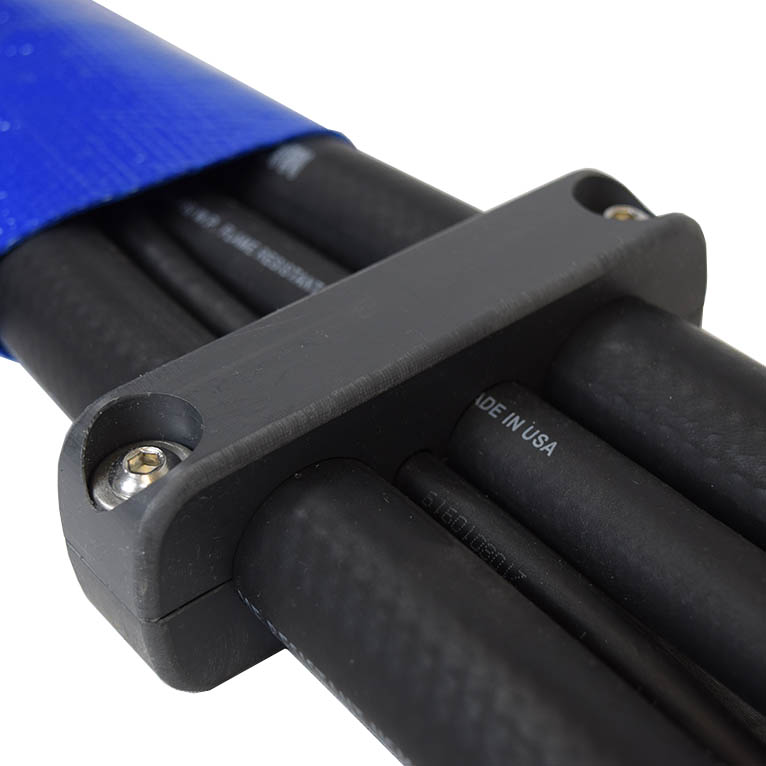

With a proven record of over 30 years, our original Bridgemaster® continues to deliver. This system is a heavy duty, lightweight, low energy, and high-deposition arc-spray metalizing system. A great option in corrosion control applications running 1/8" and 3/16" wires.

Over the years, we've designed updates to this machine to allow interchangeability with older Bridgemaster systems. This strategy has helped our customers by giving them the option to purchase a machine which has many improvements over their current machine, yet is familiar in the sense of operation, maintenance, and availability of spare parts.

Our proprietary industrial strength wire drives are CNC machined, anodized, and have an adjustable wire tension lock system. The design of the powder coated feeder cabinet and cart allows individual components to be replaced if damaged, saving both time and money.

After making a significant investment in new equipment, it helps to know you will never be stranded with a discontinued model or its parts. In another 30 years, we look forward to being able to offer continued support on our older equipment, which isn't something every manufacturer can say!

If you are shopping for new equipment, you should consider the new Bridgemaster® MKII over the original Bridgemaster. The MKII includes additional features not available on our original Bridgemaster, and comes with the added advantage of a lower price!

The Bridgemaster® Series

The Bridgemaster® Series is a lineup of twin wire arc spray systems that are heavy duty, yet portable. These low energy, high deposition arc spray machines are primarily used in the corrosion control industry to apply metalized coatings. Modular by design, these systems are capable of easy adaptation to the needs of the customer.

The Bridgemaster Series can be configured for automated or handheld, shop or field, close coupled or stand alone, while dispensing wire from either drums or spools.

Features

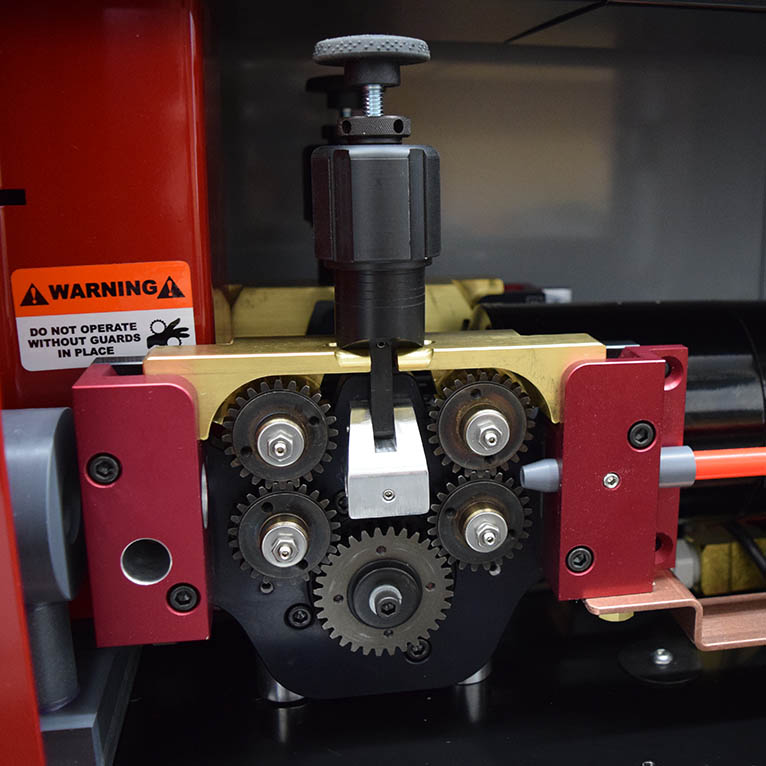

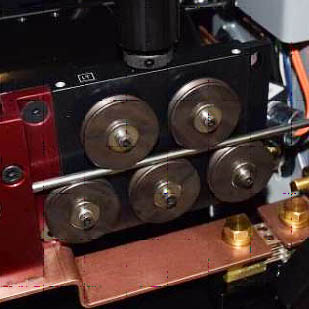

Wire Drive Assembly

The TMS proprietary precision wire drives are designed with bolt on components to ease future maintenance steps.

The simple handle/tension knob includes a feature that allows the operator to preset the wire tension and then set a lock for repeatability. Nothing hidden or complicated like some other drives available on the market today.

Applications

- Corrosion Control

- Windmills / Wind Turbine Towers

- Non-Slip Coatings

- Off-Shore Oil and Gas

- Bridges (Concrete and Steel)

- Deck Coatings

- Structural Steel Work

- Manufacturing

- Painting Facilities

- Pipe Manufacturers

- Machine Repair

- Engineering Bond Coats

- Boilers, Tanks, and Gas Cylinders

- Marine

- Shipbuilding

- Architectural

- Bearing and Seal Surfaces

- Fences and Gates

- Wear Coatings

- Shop Applications

- Field Applications

Accessories

Options and accessories can help the operator and increase productivity.

Wire Spool Shield

Our Wire Spool Shield protects the spools from contaminants and minimizes the accumulation of dust onto the metalizing wire. View More

Wire Spool Shield Cover

The Wire Spool Shield Cover provides additional protection and helps keep the wire clean; prolonging trouble-free operation. View More

Drummed Wire Dispensing Unit

Payout Systems are an excellent option for high production applications where drummed wire can be utilized. (Zinc and Zinc/Aluminum wires up to 3/16" in diameter.) View More

Equipment Carts

We have multiple cart configurations to fit the needs of your worksites and changing conditions. View More

Videos

Bridgemaster®

Arc Spray Process

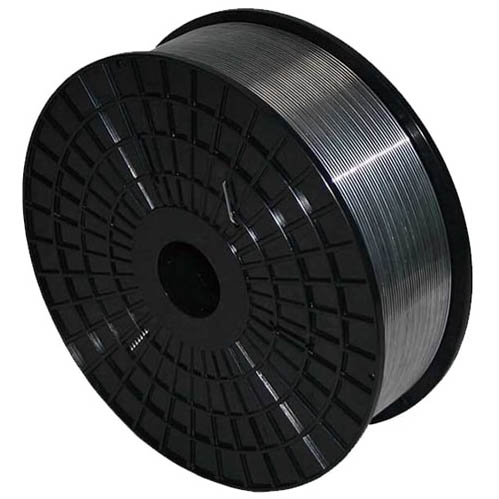

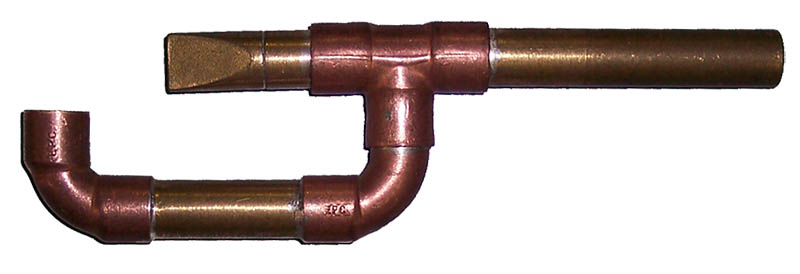

In the arc spray process, the raw material in the form of a pair of metallic wires, is melted by an electric arc. This molten material is atomised by a cone of compressed air and propelled towards the workpiece.

The molten spray solidifies on the component surface to form a dense, strongly adherent coating.

Arc Sprayed Coating Benefits

- Corrosion Protection

- Component Reclamation

- Wear Resistance

- Electrical & Thermal Conductivity

- Free Standing Shapes

Major Advantages

- The coatings are available for almost instant use with no drying or curing times.

- The deposits generally possess a higher degree of bond strength than flame sprayed deposits.

- It is more economic to operate than flame spray. No fuel is required; just compressed air and electricity.